Description

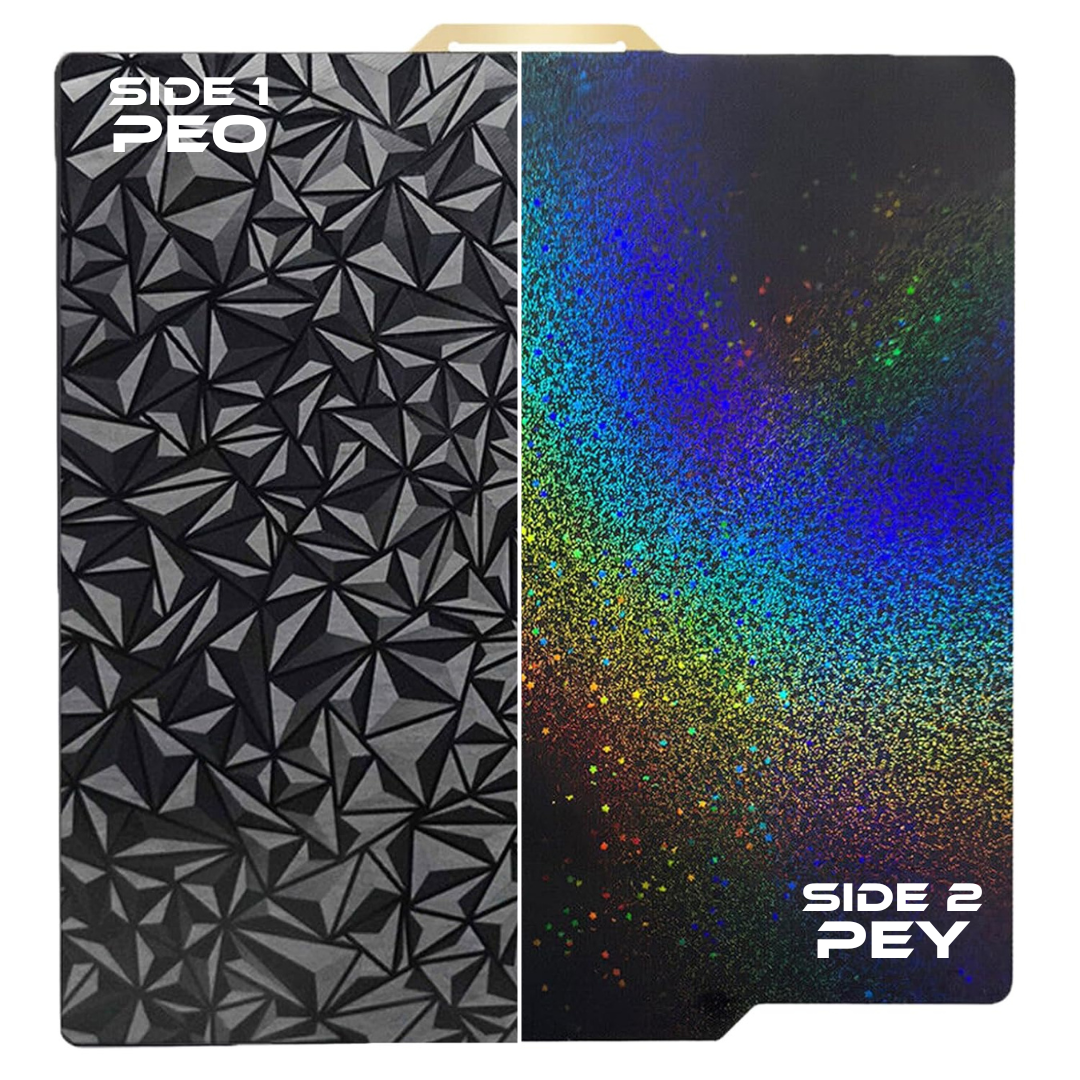

Designed for versatility and durability, METAFLEX's PEO/PEY Build Plate offers an outstanding combination of strong adhesion and easy print removal. With advanced coating technology, this build plate is perfect for a wide variety of filaments, ensuring smooth and flawless prints every time.

The PEO/PEY surface delivers exceptional durability and performance, making it ideal for demanding print jobs. Whether you're tackling small, detailed designs or large-scale projects, this build plate ensures precision, consistency, and easy removal with a flexible magnetic base.

Key Features:

- PEO/PEY Coating – Provides optimal print adhesion for materials like PLA, ABS, PETG, and more, ensuring smooth bottom layers without needing additional adhesives.

- Flexible Design – Easily remove your prints without tools, thanks to the flexible magnetic system that allows for quick and hassle-free detachment.

- Long-Lasting Durability – Engineered to withstand repeated use, the PEO/PEY surface remains reliable, offering consistent print quality across multiple jobs.

- Double Sided & Reversible – Choose between two transferable surface designs for varied finishes, giving you flexibility and control over your prints.

- Sleek and Professional Look – The modern design complements your 3D printer setup while keeping the focus on your creations.

How to Measure Your Build Plate

Step 1: Simply measure the length and width of the build plate on your FDM 3D printer.

Step 2: Cross check the measurement against our METAFLEX FDM build plate range before purchase.

Your printer's build plate will almost always be larger than its print volume, make sure you measure the full length of your build plate before selecting, or alternatively use our compatibility chart under the above tab to find your model. If you have any issues finding the right size or measuring your build plate, please get in contact with us.

Compatibility Chart

Installation & Maintenance

Installation:

- Clean Build Plate - Before installing magnetic base, thoroughly clean your build plate with IPA (Isopropyl alcohol) and a microfiber cloth to remove any dust, grease, or debris.

- Applying Magnetic Base - Peel backing paper 5cms from back edge of magnet, align both back corners of magnet with the back corners of your build plate. Once aligned push down on magnet to stick the exposed back surface. Slowly begin peeling the rest of the backing paper while pushing down and smoothing out the magnet so it sticks to the build plate with minimal air bubbles. Continue this process until backing paper is fully removed and magnet is fully applied to the surface.

- Remove Air Bubbles – To ensure surface is as flat as possible use a plastic card to push air bubbles to the edge of the magnet. Any large air bubbles that can’t be pushed out can be popped with a pin. Considerable force is required to penetrate through the magnets surface, once popped use card to smoothen out bubbled area.

- Cleaning METAFLEX Plate - Before installing your METAFLEX plate you will need to clean both sides with IPA (Isopropyl alcohol) and a microfiber cloth to remove any grease or residue that might have remained following the manufacturing process.

- Installing METAFLEX Plate – Now that the magnetic base is installed you can fit your METAFLEX Plate. Simply line up the back edge of the sheet with the back edge of the magnetic base, slowly drop the sheet into place. The magnetic pull from the base will also help pull the sheet down into place.

- Levelling and Print Removal – Installation is now complete, before printing you’ll need to level your bed as per normal and adjusting accordingly. To remove model from your METAFLEX Plate, allow some time for plate to cool so you don’t burn your fingers. Using the tabs at the front, pull the METAFLEX plate up and away from the magnetic base. Then holding opposite sides of the plate, flex up and down until model releases. For bigger models you may need to rotate sheet and flex from all 4 sides.

Maintenance:

Using IPA (Isopropyl alcohol) and a microfiber cloth, we recommend cleaning your METAFLEX plate in between each print to remove any dust, grease, or debris that may cause adhesion issues while printing.

We also recommend regular cleaning of your magnetic base with IPA (Isopropyl alcohol) and a microfiber cloth.